GREASE FITTING PROTECTOR CAP

WHY NEED CONTAMINATION CONTROL FOR MACHINE’S LUBRICATION?

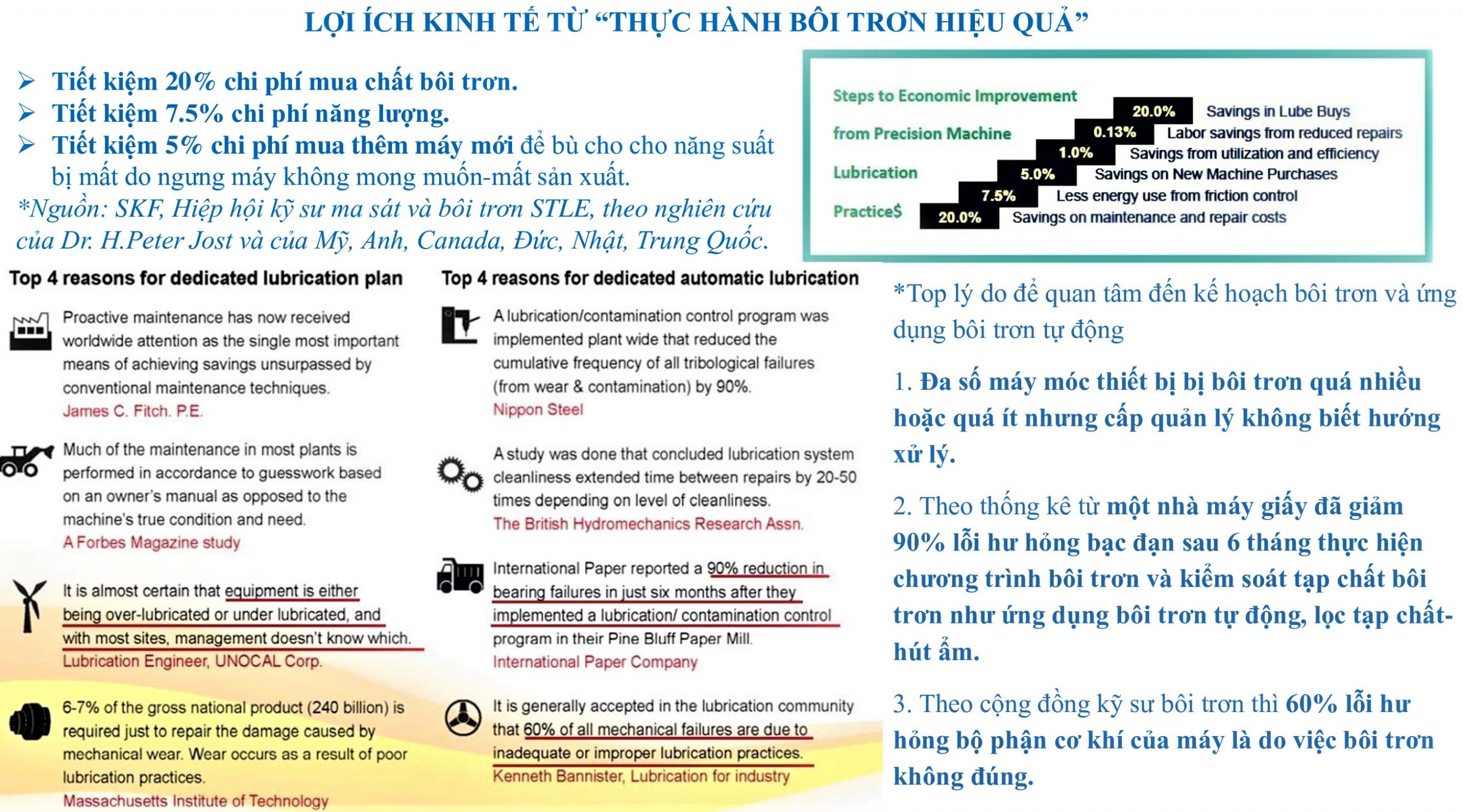

Lubricants are as critical to equipment as blood is to the human body. Just like blood, lubricants carry out the functions of transport, protection, and regulation within equipment. Lubricants ensure impurities are transported to the oil filter whilst detergents enable the suspension of impure particles, moving parts of the equipment are protected by the lubricant film preventing metal-to-metal contact, and rust build up is inhibited by additives…

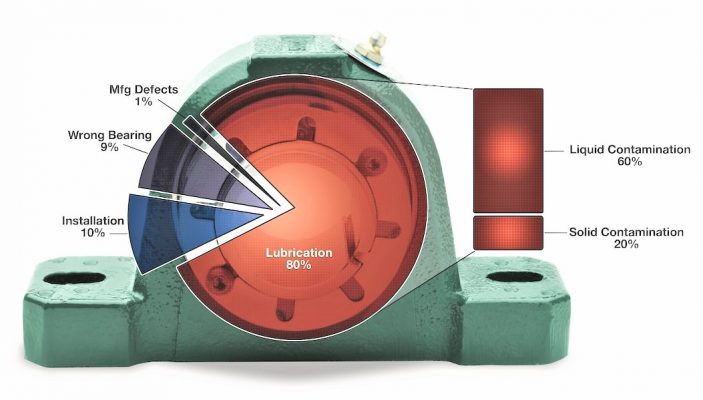

- Every Machine have the ISO 4406 level regarding Particle level and Moisture level to define the purity of the used fluid for the machine in unit ppm-Part Per Million.

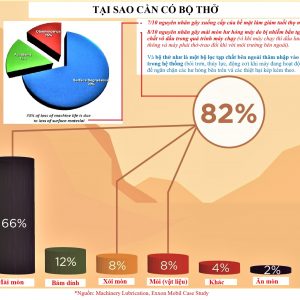

- Most failures of Bearings, Gearboxes, and Machine’s transmissions parts are related to contamination to the fluid of oil lubrication or hydraulic oil.

3. Otherwise the Machine will be subjected to “ill” of vibration, wear, hot…and damage soon like this Video.

That’s why the Grease nipple protector cap is used…

*Pictures sources: Machinery Lubrication, Yorkmh-USA, tribology.co.uk, SKF, Descase, Leanmanufacturing.